Introduction to Hole Processing Methods - Drilling, Reaming, Countersinking, and Reaming

Date: 2025-06-09 Categories: Blog Views: 5585

drilled hole

The method of machining holes in solid material with a twist drill is called drilling. General machining can be achieved with a dimensional tolerance class of IT14 to IT11 and a surface roughness Ra value of 50 to 12.5 μm.

Commonly used drilling machines are: benchtop drilling machines, vertical drilling machines and rocker arm drilling machines.

1. Drilling machine

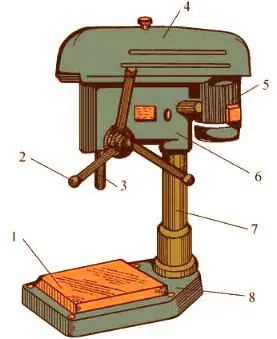

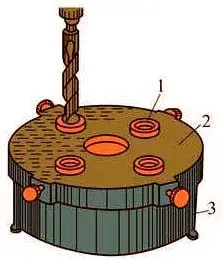

(1) desktop drilling machine referred to as desktop drill (Figure 1), is a small machine tool, placed in the clamping table to use. Its drilling diameter is generally below 12mm. Mainly used for processing small workpieces on a variety of holes, clamping in the most used.

Figure 1 Benchtop drilling machine

1-Table 2-Feeding handle 3-Spindle 4-Belt cover 5-Motor

6-Spindle holder 7-Column 8-Holder

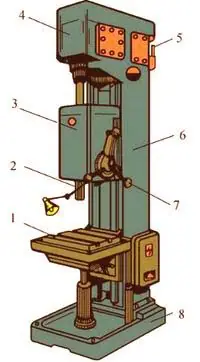

(2) Vertical drilling machine referred to as vertical drill (Figure 2), generally used to drill holes in medium-sized workpieces, its specifications with the maximum drilling diameter. Commonly used 25mm, 35mm, 40mm, 50mm and so on.

Figure 2 Vertical Drilling Machine

1-Table 2-Spindle 3-Feed box 4-Spindle gearbox

5-Motor 6-Column 7-Feeding handle 8-Machine base

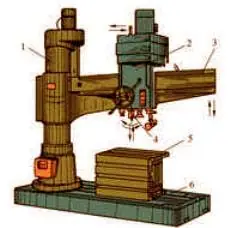

3) Rocker arm drilling machine The rocker arm drilling machine has a rocker arm that can rotate around the column (Figure 3). The spindle box can be moved laterally on the arm, and can be adjusted with the arm up and down along the column, so the operation can be easily adjusted to the center of the holes to be drilled, and the workpiece does not need to move. Rocker arm drilling machine has a wide range of processing, can be used to drill all kinds of screw holes, threaded bottom holes and oil holes of large workpieces.

Figure 3 Rocker arm drilling machine

1-column 2-spindle box 3-rocker arm 4-spindle 5-table 6-machine base

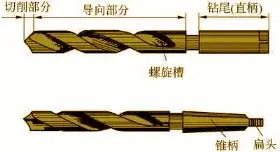

2、Twist drill

Twist drill is the main tool for drilling holes, which is composed of a cutting part, a guiding part and a shank, as shown in Figure 4. The diameter is generally straight shank drill when the diameter is less than 12mm, and taper shank drill when it is more than 12mm.

Figure 4 Twist drill

The twist drill has two symmetrical spiral grooves, which are used to form the cutting edge and for the transportation of cutting fluid and chip removal. The cutting part of the front end (Figure 5) has two symmetrical main cutting edges, and the angle 2φ between the two edges is called the sharp angle. The intersection line of the two top surfaces is called the transverse edge. The two edge bands on the guiding part play a guiding role in cutting, and at the same time reduce the friction between the drill bit and the hole wall of the workpiece.

3. Drilling operation

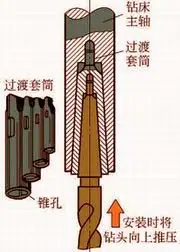

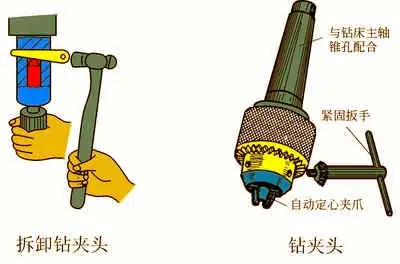

1) Clamping of drill bits Clamping methods for drill bits vary according to the shape of their shanks. Taper shank drills can be mounted directly into the spindle hole of the drilling machine, and smaller drills can be mounted with a transition sleeve (Fig. 6); straight shank drills are generally mounted with a drill chuck (Fig. 7).

Figure 6 Mounting a taper shank drill

Figure 7 Figure 8

The drill chuck or transition sleeve is removed by inserting the wedge with the rounded edge upward into the tapered hole in the side of the drill press spindle, holding the drill chuck with the left hand, and striking the wedge with a hammer with the right hand to remove the drill chuck (Fig. 8).

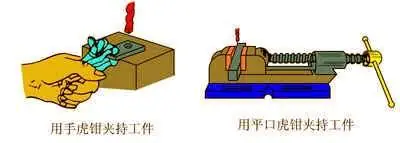

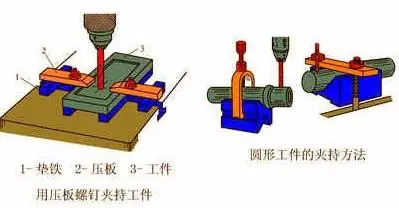

(2) Workpiece clamping Safety accidents in drilling are mostly caused by incorrect workpiece clamping methods. Therefore, attention should be paid to the workpiece clamping. Small and thin-walled parts drilling, to use hand vise clamping workpiece (Figure 9). For medium-sized parts, clamp in a flat vise (Figure 10). Large and other workpieces not suitable for clamping in a vise can be fixed directly to the drill press table with platen screws (Fig. 11). To drill holes in round shafts or sleeves, the workpiece must be pressed against a V-iron to drill the holes (Fig. 12). In batch and mass production, drilling fixtures are widely used for drilling holes (Fig. 13).

Figure 9 Figure 10

Figure 11 Figure 12

Figure 13 Drilling mold

1-drill sleeve; 2-drill mold; 3-workpiece

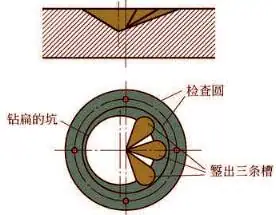

(3) according to the line drilling before drilling should be in advance in the center of the hole punching the sample punch, drilling, first of all, aligned with the sample punch eye test drilling a shallow pit, such as bias, can be used to re-punch sample punching to correct, but also can be used burin burin out a few grooves to correct (Figure 14). When drilling, the feed rate should be uniform, will be drilling through, the feed amount should be reduced. Drill tough materials to add cutting fluid. When drilling deep holes (the ratio of hole depth L to diameter d is greater than 5), the drill must often exit the chip removal.

Fig. 14 Burin correction in case of drilling deviation

ream (i.e. widen a hole)

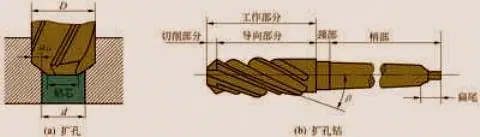

The enlargement of a drilled hole with a reaming drill is called reaming (Fig. 1b). The tool used for reaming is the reaming drill, as shown in Figure 1a. Due to the reaming drill rigidity, no transverse edge, good guidance, so the reamed hole size tolerance level has improved, up to IT10 ~ IT9, surface roughness Ra value of 3.2μm. reaming can be used as the final machining, but also as a reaming pre-machining.

Figure 1 Reaming Drill and Reaming

countersink

A flat surface of a hole or tab of a certain shape is machined by countersinking on the surface of the hole, which is called countersinking. Examples include countersinking cylindrical countersinks, countersinking conical countersinks, and countersinking the plane of a tab used to place a washer.

ream (i.e. cut a hole)

Reaming is the finishing of holes. Reaming can be divided into rough reaming and fine reaming. Fine reaming as shown in Figure 3a, its processing allowance is small, only 0.05 ~ 0.15mm, the size tolerance level up to IT8 ~ IT7, surface roughness Ra value of up to 0.8μm. reaming before the workpiece should be drilled an expansion (or boring) and other processing.

1、Reamer

There are two types of reamers: hand reamers and machine reamers (Figure 3b). Hand reamers are straight shanked and have a long working part. Machine reamers are mostly tapered shanks and can be mounted on drilling machines, lathes or boring machines to ream holes. The working part of the reamer consists of a cutting part and a finishing part. The cutting part is tapered and is responsible for the cutting work; the polishing part plays the role of guiding and polishing. The reamer has 6 to 12 cutting edges, and the cutting load of each edge is light.

2、Steps and methods of hand reaming cylindrical holes

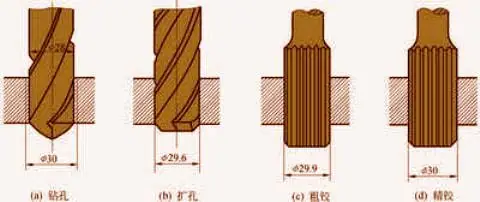

(1) According to the hole diameter and hole accuracy requirements, to determine the hole processing method and the machining allowance between processes, such as Figure 4 for the higher precision φ30 hole processing.

Fig. 4 Hole machining method and process allowance

2) Drill or ream the holes and then ream them.

(3) hand reaming, both hands force evenly, according to the clockwise direction of the reamer and slightly force downward pressure, at any time can not be reversed, otherwise, the chips crowded reamer, scratching the hole wall, so that the reamer blade chipped, reamed out of the hole is not smooth, not round, and inaccurate.

(4) During the reaming process, if it does not turn, do not wrench hard, but carefully pull out the reamer and check whether the reamer is stuck by chips or meets a hard point. Otherwise, the reamer will be broken or the cutting edge will be chipped.

(5) The size of the feed should be appropriate and even, and constantly add cooling lubricant.

6) After reaming the hole, exit the reamer by rotating it clockwise.