High-pressure die casting, gravity casting and low-pressure casting pressure mold manufacturing is essentially the process of tailoring high-precision metal cavity tooling for different casting processes according to the power and manner of filling the cavity with liquid metal. Among them.High Pressure Die CastingMolds need to withstand extremely high injection pressures and high-speed filling, usually using high-strength hot work mold steel, and designed with precise ejector, core extraction and cooling systems to safeguard the life and heat dissipation under millisecond filling;Gravitational castingThe mold relies on the self-weight filling of the liquid metal, the structure is relatively simplified, focusing on reasonable exhaust and sequential solidification design, and a wider choice of materials;Low-pressure castingThe molds are tightly integrated with a sealed and insulated pouring system, where the workpiece is smoothly filled from the bottom up under low pressure gas, and the mold design puts special emphasis on vertically oriented solidification and shrinkage channels. In spite of the different power sources, all three types of molds are designed for high accuracy in cavity dimensions, excellent release angles and coating treatments to ensure that the castings are densely organized and clearly defined under pressure, low pressure or no pressure at all.

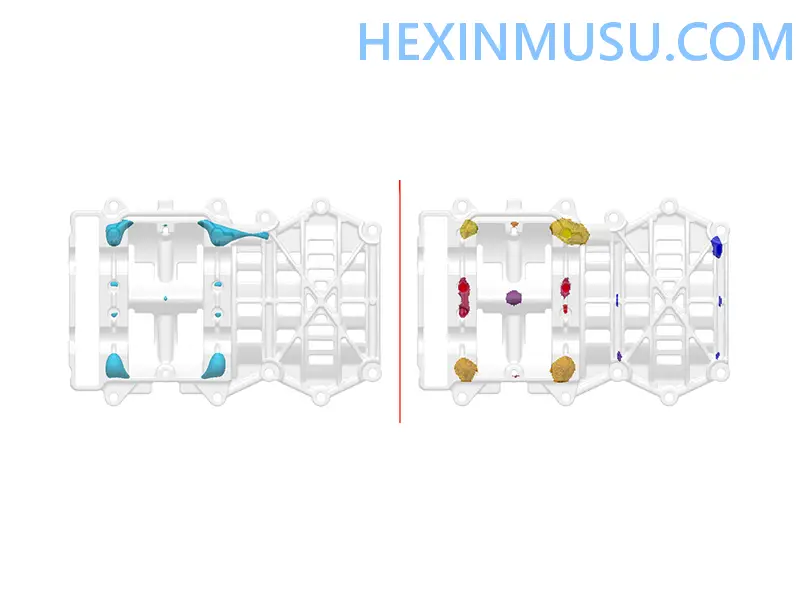

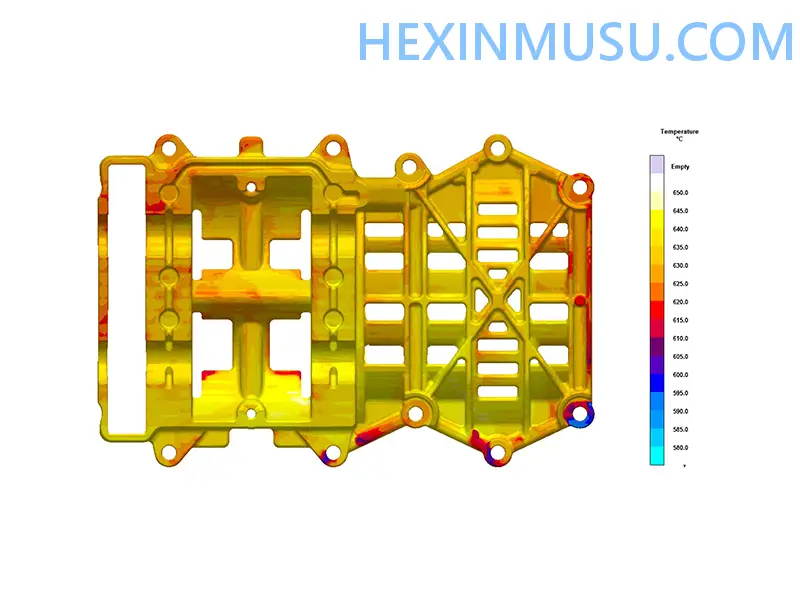

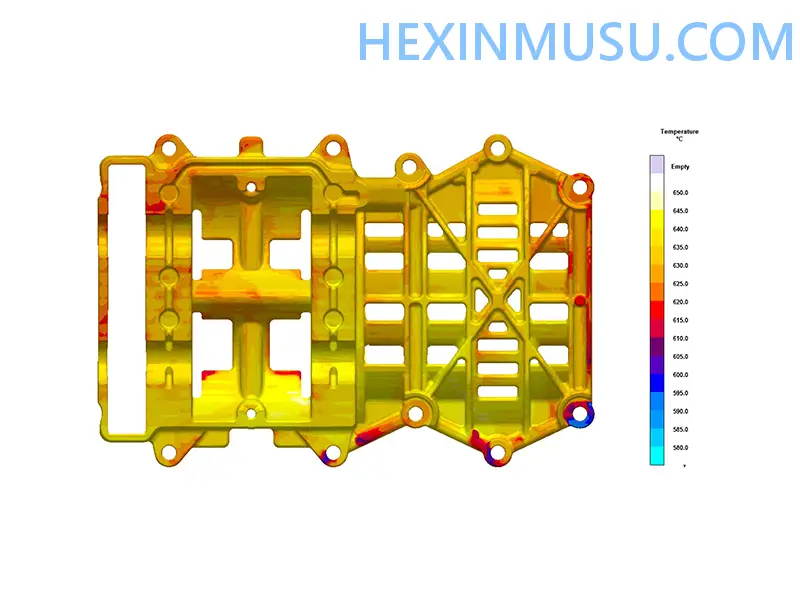

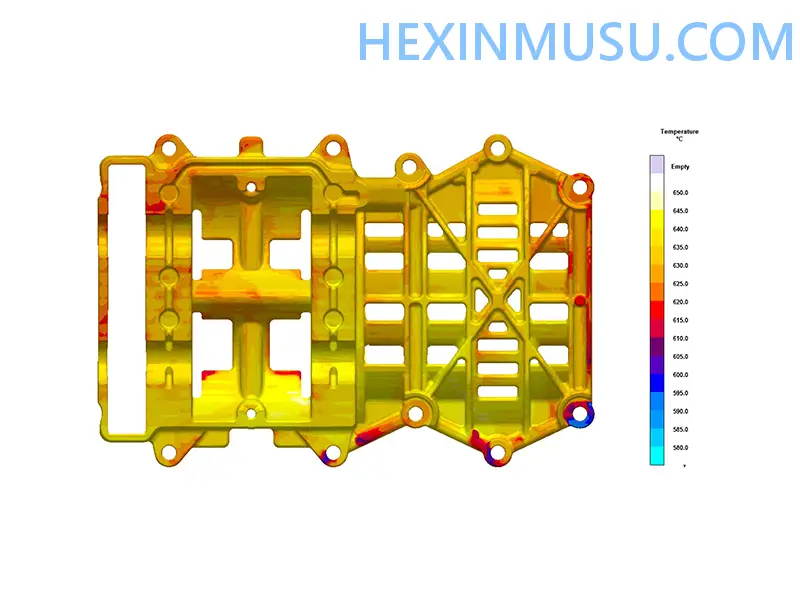

1. Design and Review3D/2D graphic design

2. Materials and roughingCore Roughening

3. Finishing and special machiningPrecision milling after heat treatment

4. Assembly and commissioningMold Fit Mold

5. Acceptance and deliveryInspection of dimensions, pre-delivery maintenance