About

We are proud to have supplied a wide range of high quality aluminum die castings for over 20 years to customers around the world across multiple industries.

About Ningbo Hersin Mold Co.

Ningbo Hexin Mould Co., LTD., founded in November 2010, is located in Ningbo Beilun, the hometown of mould in China. It is a professional company engaged in the research and development, application, production and sales of aluminum alloy casting mould. (Aluminum alloy casting company based on auto parts) At present, the company is committed to the expansion and development of low-pressure casting new energy field.

The main business areas of the company are as follows:

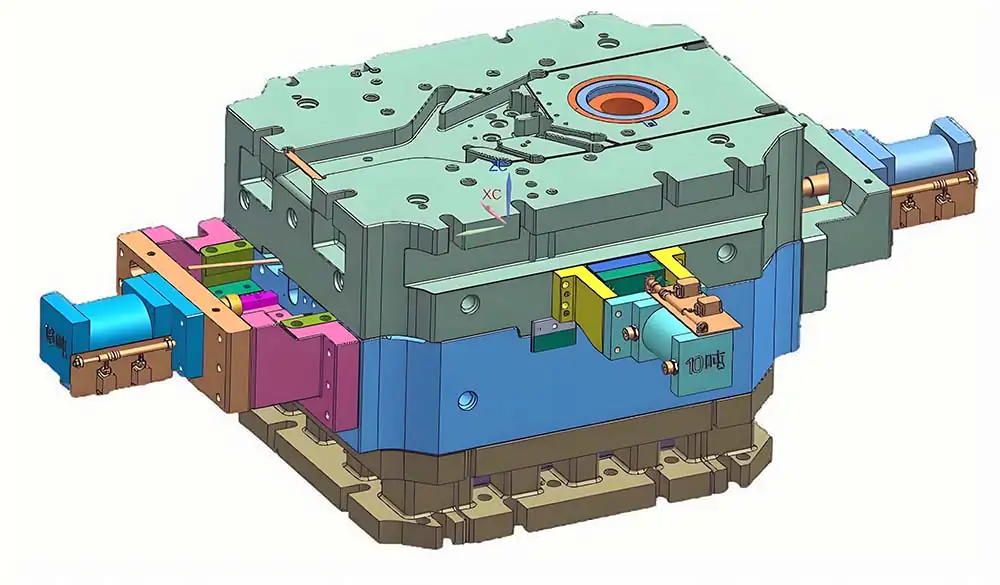

1, low voltage mold manufacturing; 2, low voltage product production;

3. Gravity mold manufacturing; 4. Gravity product production;

5, High pressure mold manufacturing; 6, High pressure product production;

7, mold structure analysis; 8, product molding analysis

Diversified development, focusing on the manufacture of aluminum alloy products, has been the company is committed to aluminum alloy and its related industries casting production.

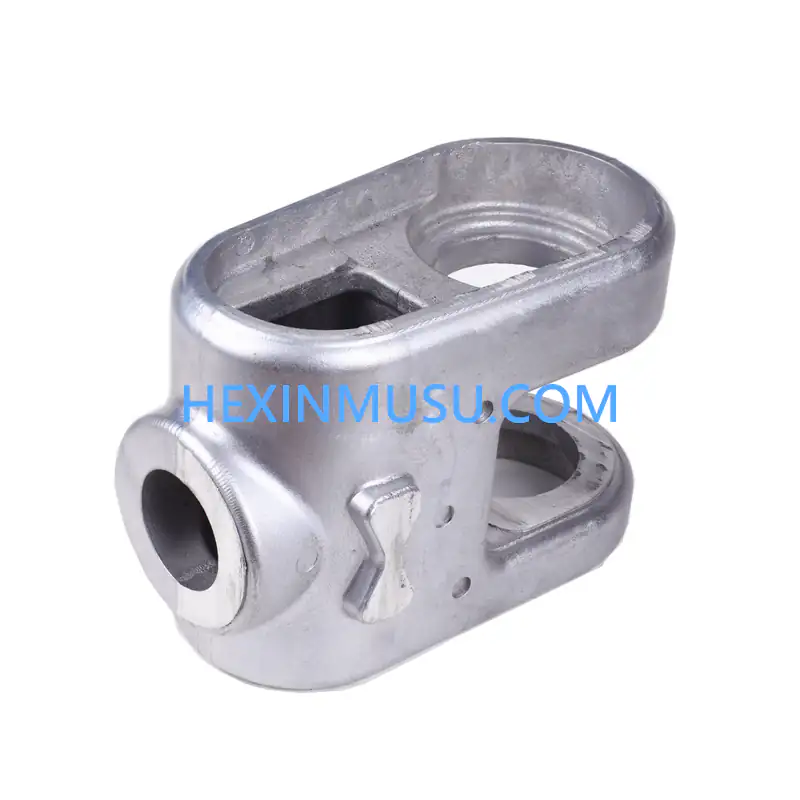

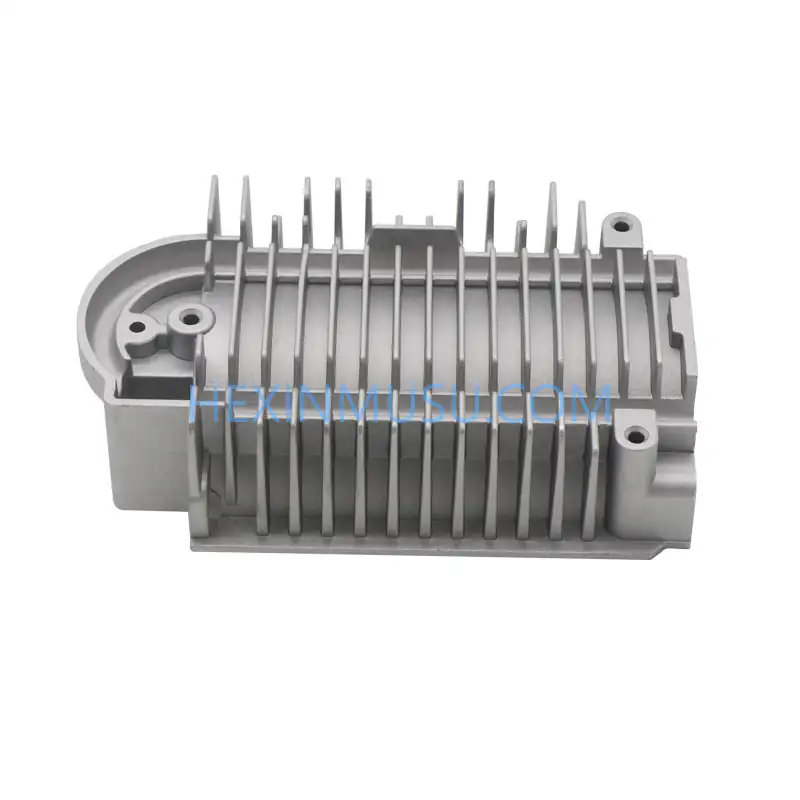

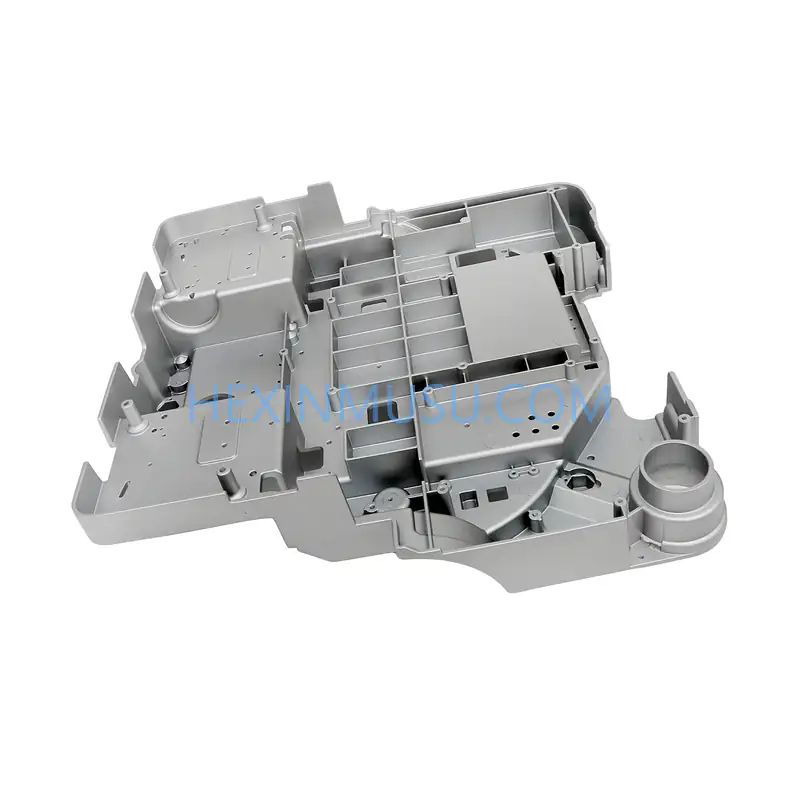

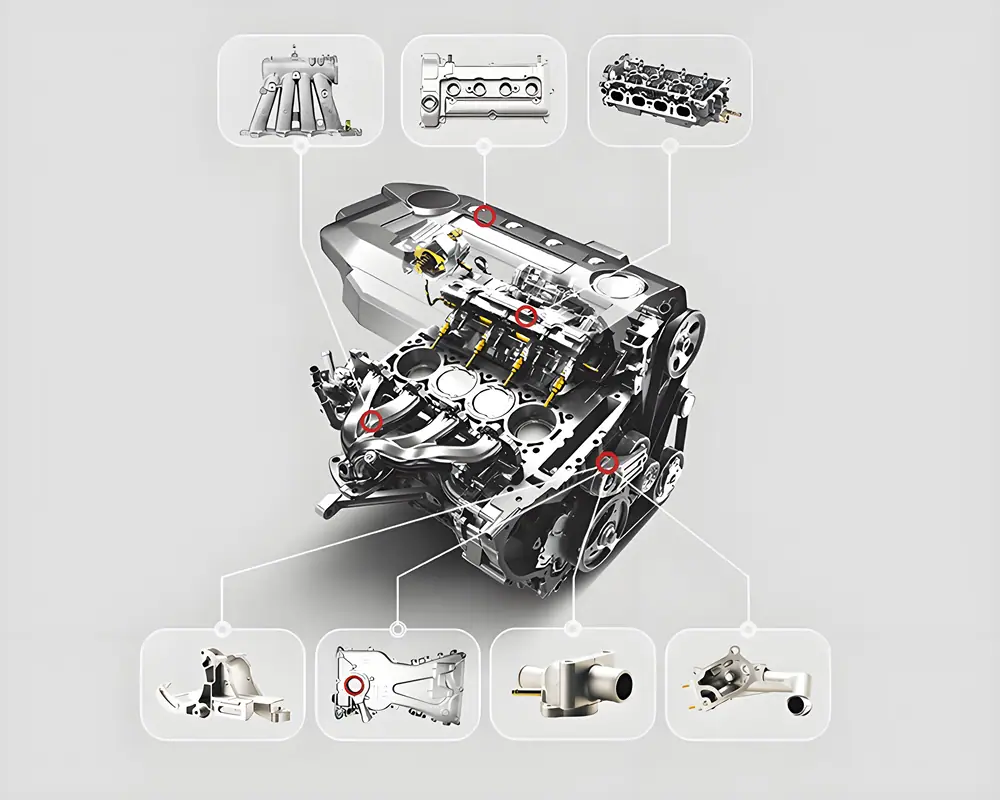

HEXIN PRODUCT SHOW

In the development and production of aluminum casting (pressure casting, gravity casting, low pressure casting) projects, Hershey is recognized as a safe and reliable partner by our customers worldwide. We take pride in the satisfaction of our customers.

Reasons for choosing Ningbo Huxin as a supplier

As a technology leader in the field of aluminum alloy casting for more than 20 years, Ningbo Hexin has become a preferred partner in the automotive, new energy and high-end equipment manufacturing fields by virtue of the layout of the whole industrial chain and continuous innovation. The following is an analysis of the core competitiveness of the enterprise from the three dimensions of intellectual ability, quality control and technology cross-border:

✅ Smart Express

Digital full-process production, intelligent die-casting clusters to support rapid customization, delivery cycle speed up beyond the industry standard, yield rate is steadily high.

✅ Military quality

International standard certification system, strict control of casting internal defects, double precision testing to ensure the stability of extreme working conditions.

✅ Cross-border innovation

Multi-field material database support, 5G heat dissipation/photovoltaic bracket technology breakthroughs, adapted to new energy, high-end equipment and other cutting-edge needs.